3D Printing

Accelerate productivity of plastic additive manufacturing process.

The productivity of additive manufacturing, especially for plastic materials, can be significantly increased by using a multi-beamlet scanning system. Linear PLV™ can handle more than 800W CW laser at 1064nm wavelength.

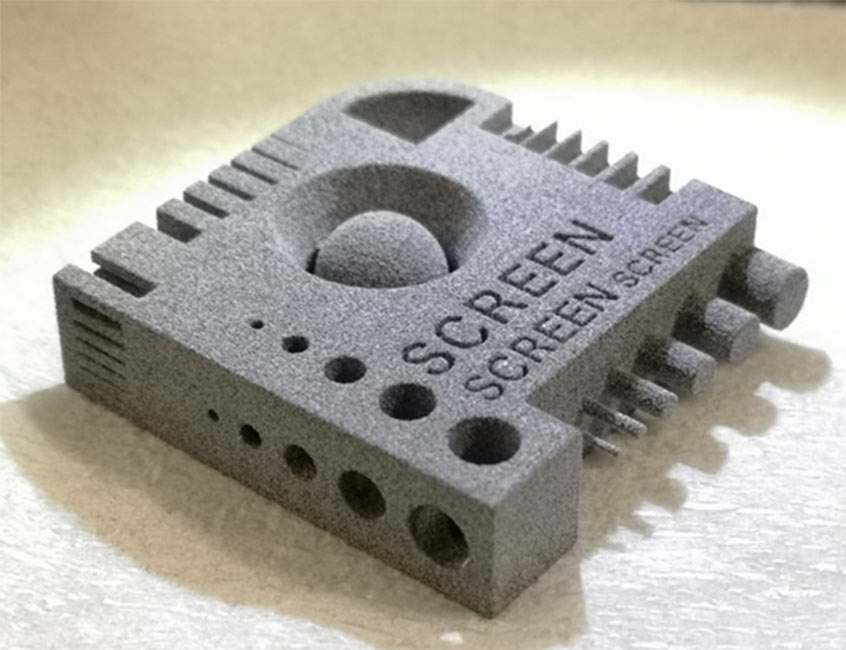

SCREEN demonstrated plastic additive manufacturing with Galvo scanning laser system. Since nominal plastic material does not absorb near infrared wavelengths, black carbon is mixed in the plastic compound. The resolution on the powder bed was 25 µm, which was 4 times higher than conventional CO2 single beam scanning system. Scanning speed is estimated to be 7 times faster for building reference parts compared to existing AM equipment of single beam CO2 laser systems.

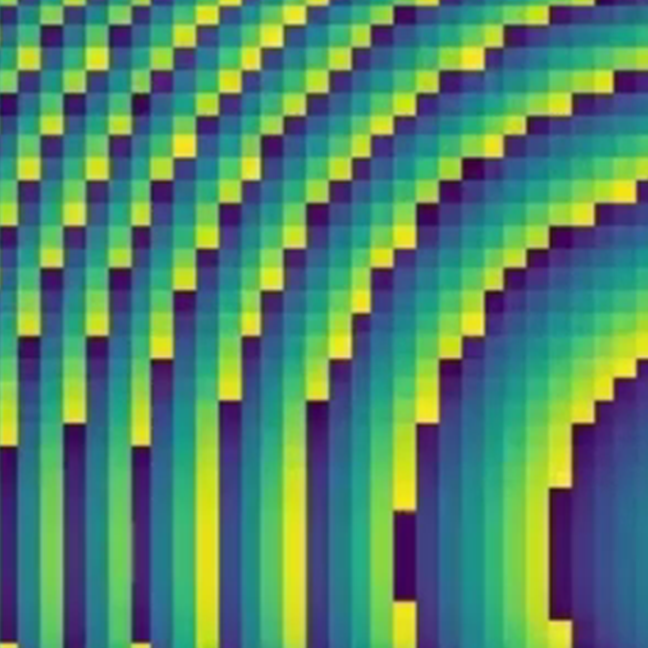

Maskless Lithography

Embracing the future with maskless solutions.

UV amplitude modulation for high throughput sub-micron resolution maskless lithography.

Laser Material Processing

Higher productivity in laser material processing.

Black marking for logos, text, and even halftone images. Plus etching, polishing, thin film removal, and more.

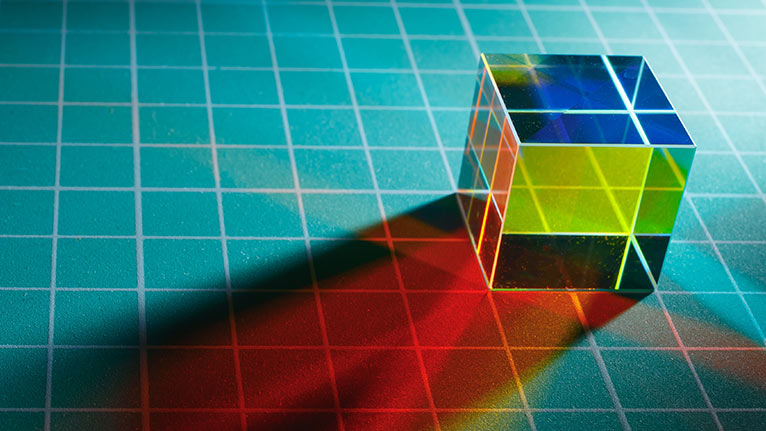

Spectral Shaping

Effective spectral shaping for a broad range of applications.

Dynamically shape light spectra at high speeds for industrial, medical and communication applications.

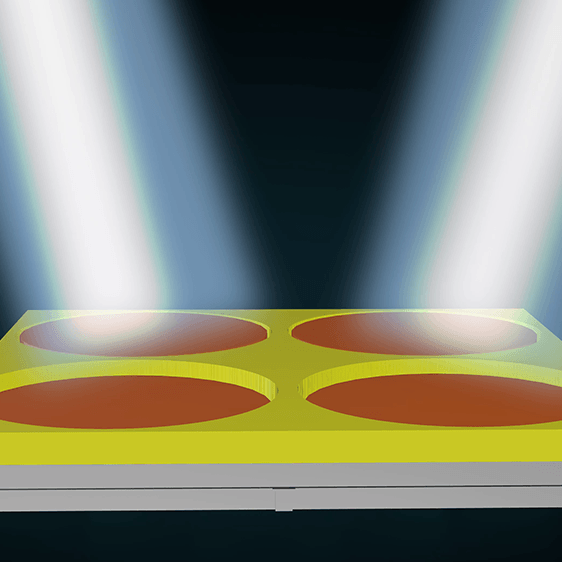

3D Printing

Accelerate productivity of plastic additive manufacturing process.

High power CW patterned swaths for intricate and large piece plastic sinter AM at high throughput.

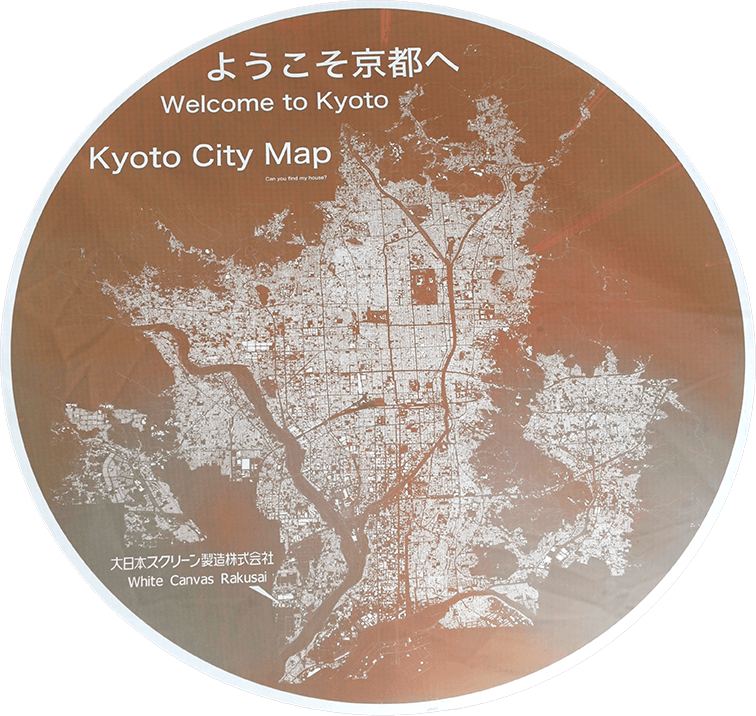

Digital Printing

CTP plate-setters of the highest productivity in the world.

Beautiful 2400 dpi print plates created in record time.

Emerging Technologies

Endless possibilities with high speed MEMS.

Microscopy, novel computing, optical communications, sensing - endless possibilities for amplitude and phase modulation.