Applications

Technology for many industrial, medical and consumer markets.

Silicon Light Machines’ thin-film MEMS technology enables high-speed, high-power phase and amplitude modulators for use in a wide variety of applications in industrial, medical and consumer markets.

First, the borderless pixels and high-contrast, true grayscale modulation was used in beautiful projector display systems. These same attributes along with high-power handling are now used in graphic arts and maskless lithography.

The linear PLV large pixels allow for higher powers and fluences, which enables super high-throughput, high-resolution systems for multi spot laser material processing such as laser marking and 3D printing. New applications for phase modulators are emerging that require the unique attributes of the thin-film MEMS: 100kHz+ frame rates, high-power handling and UV-NIR wavelength handling. These new applications range from high-power beam forming for industrial applications to high-speed holographic control for sensing and free-space optical communication.

Maskless Lithography

Embracing the future with maskless solutions.

UV amplitude modulation for high throughput sub-micron resolution maskless lithography.

Laser Material Processing

Higher productivity in laser material processing.

Black marking for logos, text, and even halftone images. Plus etching, polishing, thin film removal, and more.

Spectral Shaping

Effective spectral shaping for a broad range of applications.

Dynamically shape light spectra at high speeds for industrial, medical and communication applications.

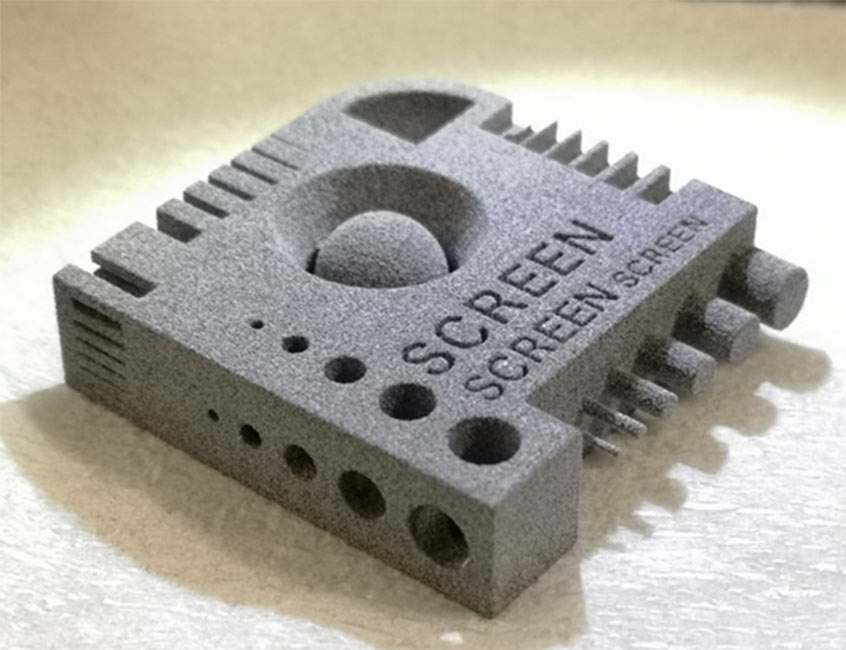

3D Printing

Accelerate productivity of plastic additive manufacturing process.

High power CW patterned swaths for intricate and large piece plastic sinter AM at high throughput.

Digital Printing

CTP plate-setters of the highest productivity in the world.

Beautiful 2400 dpi print plates created in record time.

Emerging Technologies

Endless possibilities with high speed MEMS.

Microscopy, novel computing, optical communications, sensing - endless possibilities for amplitude and phase modulation.