Digital Printing

CTP plate-setters of the highest productivity in the world.

Computer-to-Plate or “CTP” imaging refers to direct transfer of digital content onto the aluminum plates used in offset printing. This involves exposing meter-scale flexible aluminum substrates to high-intensity, near-infrared laser light in order to thermally modify the surface. High-laser power levels are required: up to 80W on a single GLV® device and power densities of 10kW/cm2.

Resolution and throughput are key attributes for these systems. CTP image content is characterized by binary and halftone (dot) images up to 4000 dpi (6.4 µm features), and SCREEN plate-setters can process up to 70 B1 format plates per hour.

The high-speed, high-power handling, and precise intensity and timing control of the GLV® make it an ideal modulator for this application. SCREEN has been selling the GLV®-based plate-setters since 2003 and has sold more than 5,000 units in total while maintaining the top market share in the world.

SCREEN PlateRite HD 8900 - Computer-to-Plate (CTP)

Resources

Further information and application notes

Computer-to-plate printing using the Grating Light Valve™ device

Describes the successful implementation of the Grating Light Valve (GLV®) device as a spatial light modulator in commercial computer-to-plate (CtP) systems for the graphic arts industry.

Maskless Lithography

Embracing the future with maskless solutions.

UV amplitude modulation for high throughput sub-micron resolution maskless lithography.

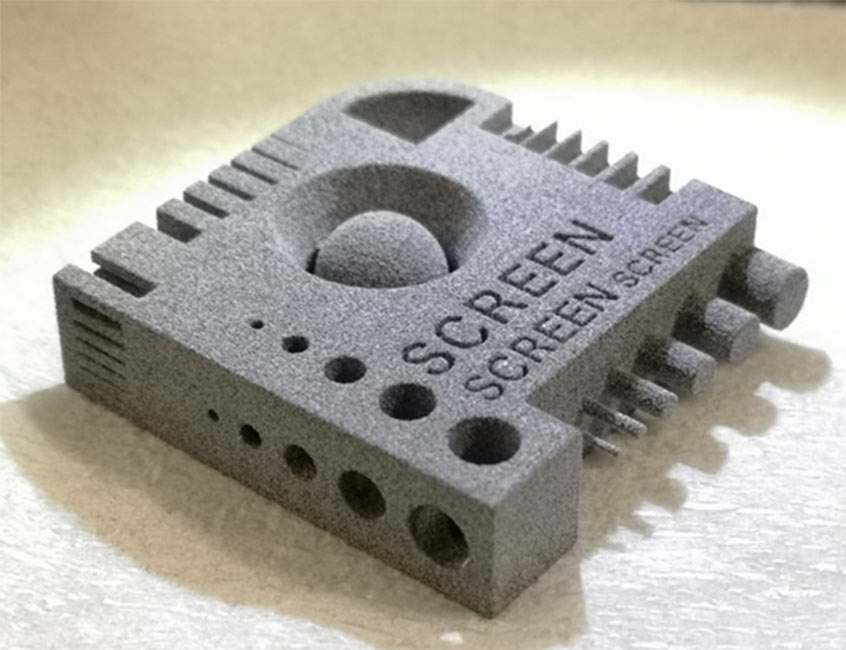

Laser Material Processing

Higher productivity in laser material processing.

Black marking for logos, text, and even halftone images. Plus etching, polishing, thin film removal, and more.

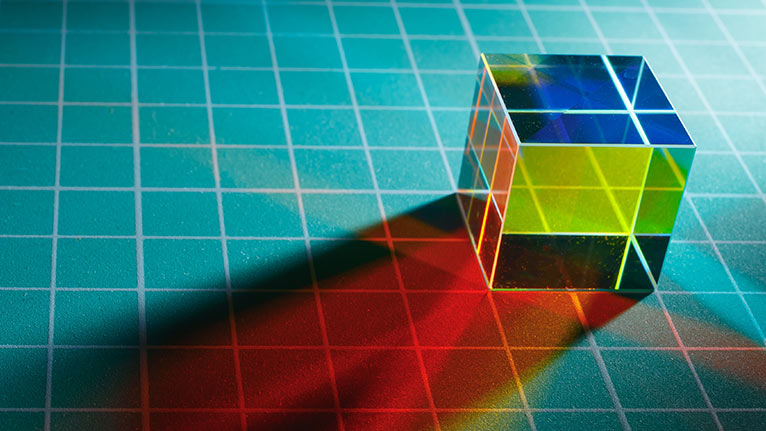

Spectral Shaping

Effective spectral shaping for a broad range of applications.

Dynamically shape light spectra at high speeds for industrial, medical and communication applications.

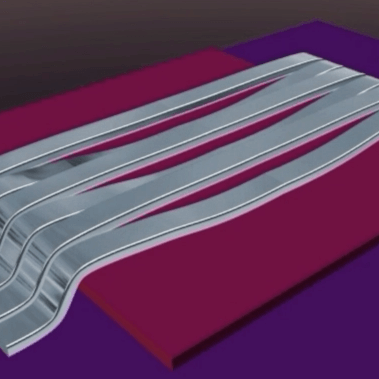

3D Printing

Accelerate productivity of plastic additive manufacturing process.

High power CW patterned swaths for intricate and large piece plastic sinter AM at high throughput.

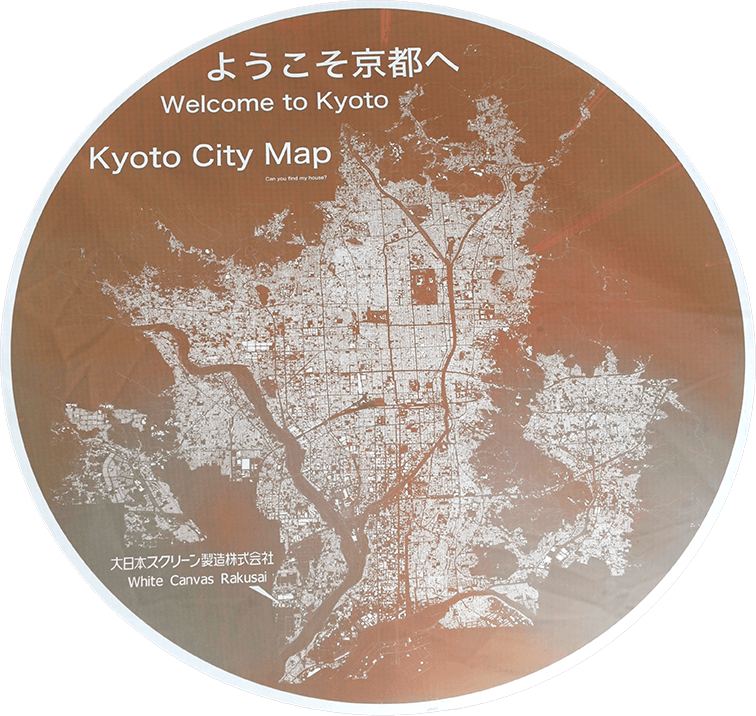

Digital Printing

CTP plate-setters of the highest productivity in the world.

Beautiful 2400 dpi print plates created in record time.

Emerging Technologies

Endless possibilities with high speed MEMS.

Microscopy, novel computing, optical communications, sensing - endless possibilities for amplitude and phase modulation.