Laser Material Processing

Higher productivity in laser material processing.

The use of lasers for industrial marking and materials processing has seen rapid growth in recent years. Here, a high-intensity laser is used to mark, melt or in other way modify the exposed material relative to its surrounding.

Until now, the dominant approach in this application has resulted in a single beam raster over the work surface by galvo scan mirrors. While the focused beam is effective in generating the intensity needed to modify the material, the throughput of such systems is limited as the area is written sequentially using just a single beam.

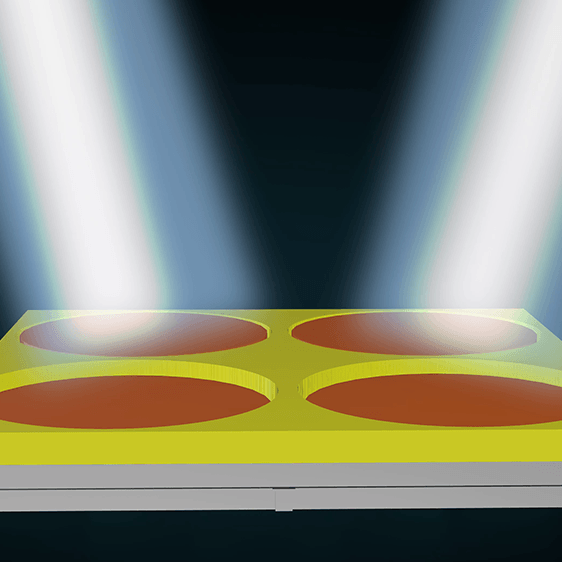

Recent advances in total available laser power are enabling higher productivity alternatives. For example, by replacing the scan mirror with a spatial light modulator, the single beam is turned into hundreds or thousands of beamlets all writing to the surface in parallel. Clearly, this throughput boost requires a spatial light modulator with outstanding power-handling capability.

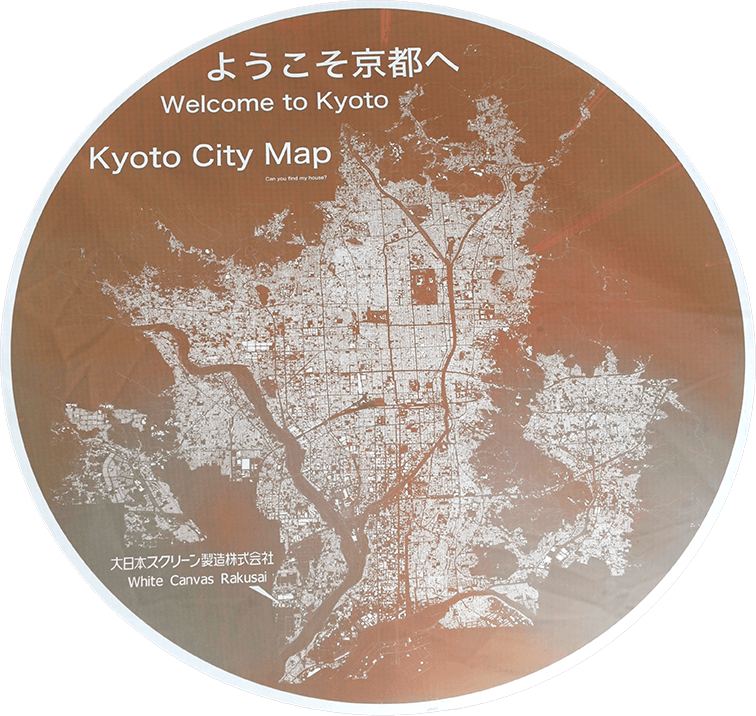

We have created a laser marking system to demonstrate the benefits of using the PLV™. This system uses a 1064 nm, 10ps, 100W laser to illuminate the PLV™. The PLV™ is then imaged with a de-magnification of 10 times to give high fluence with 10 µm resolution at the work surface. This system was designed for making black marks on stainless steel, but has also been used on aluminum, plastic and graphite.

Half tone marking for grayscale images on stainless steel.

Resources

Further information and application notes

High Power MEMS Planar Light Valve

The PLV™ supports modulation of over 500W of laser power for materials processing. It provides a line beam with 1088 individually addressable pixels and 200kHz switching speed. A custom optical head complements the PLV™.

High Throughput Materials Processing

An overview of how the Planar Light Valve (PLV™) spatial light modulator enables high-throughput, multi-beam materials processing for applications like laser marking and micromachining.

Maskless Lithography

Embracing the future with maskless solutions.

UV amplitude modulation for high throughput sub-micron resolution maskless lithography.

Laser Material Processing

Higher productivity in laser material processing.

Black marking for logos, text, and even halftone images. Plus etching, polishing, thin film removal, and more.

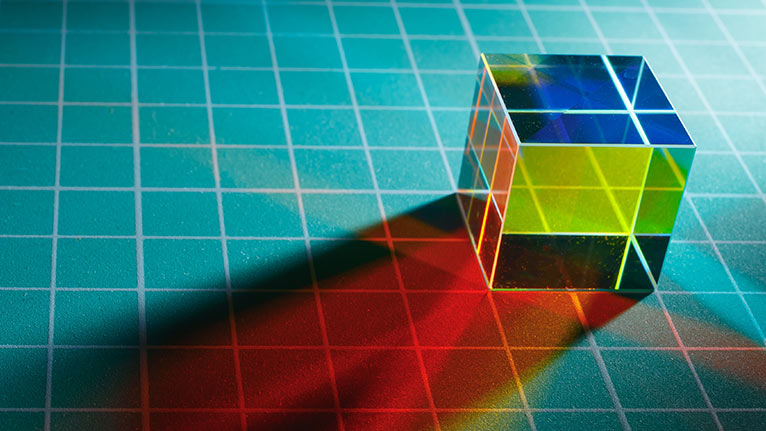

Spectral Shaping

Effective spectral shaping for a broad range of applications.

Dynamically shape light spectra at high speeds for industrial, medical and communication applications.

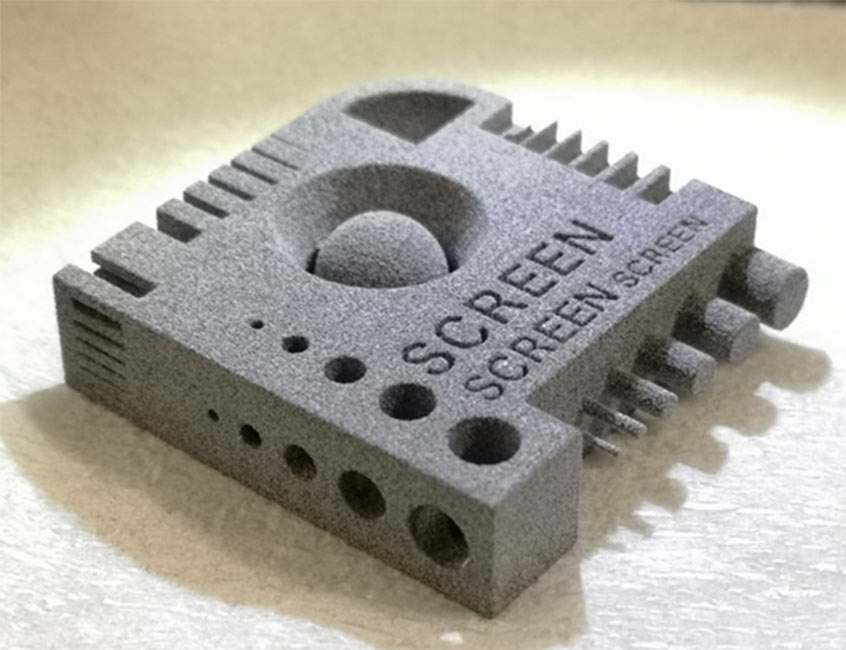

3D Printing

Accelerate productivity of plastic additive manufacturing process.

High power CW patterned swaths for intricate and large piece plastic sinter AM at high throughput.

Digital Printing

CTP plate-setters of the highest productivity in the world.

Beautiful 2400 dpi print plates created in record time.

Emerging Technologies

Endless possibilities with high speed MEMS.

Microscopy, novel computing, optical communications, sensing - endless possibilities for amplitude and phase modulation.