Planar Light Valve (PLV™)

Expand into New Dimensions with PLV™

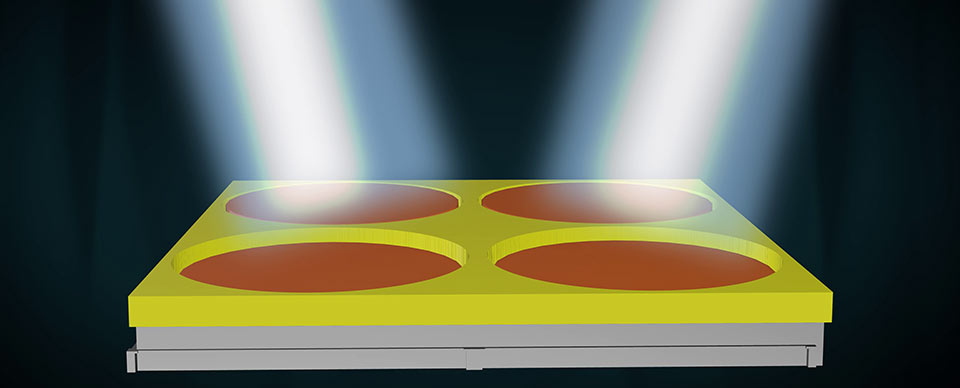

The Planar Light Valve (PLV™) is a two-dimensional analog of the one-dimensional GLV®. It inherits the desirable properties of the GLV® (high speed, high-power handling, analog grayscale) and offers new advantages such as higher pixel counts, increased power handling, and larger étendue. Most notably, the PLV™ removes the restriction of line illumination associated with the GLV®. This allows the PLV™ to be flood-illuminated, similar to conventional spatial light modulators.

Principle

Large aperture diffractive modulation

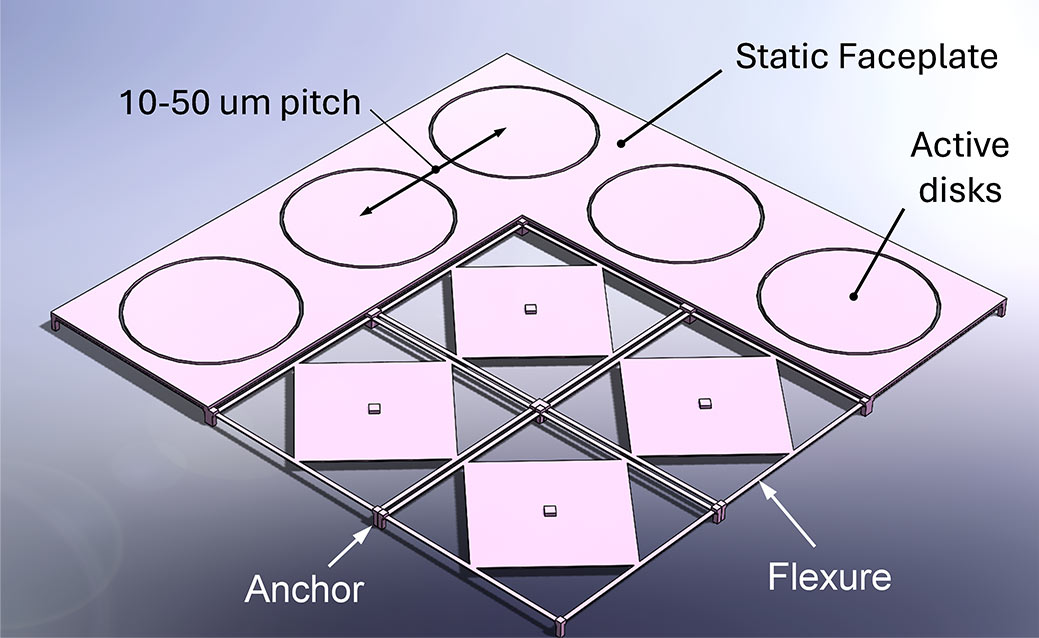

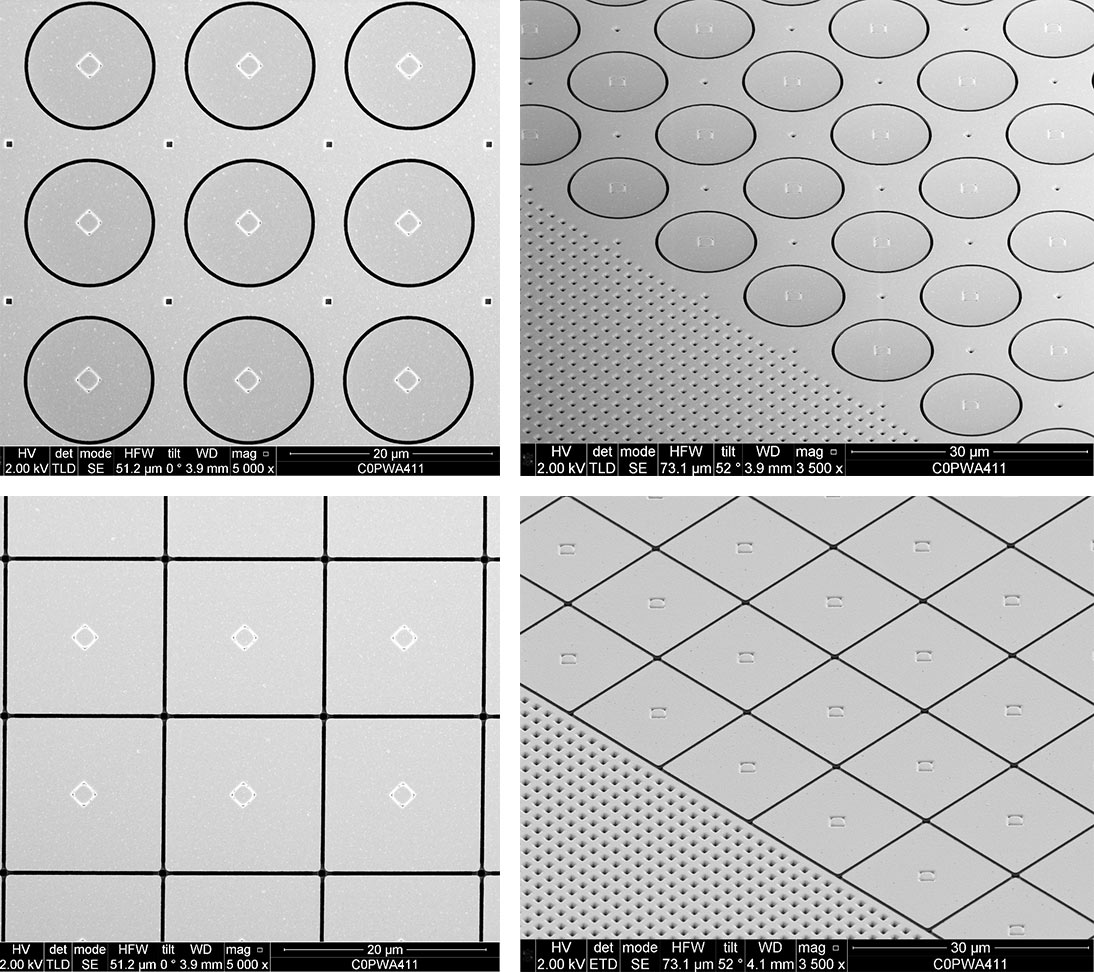

The PLV™ is a dual-layer MEMS composed of an exposed upper faceplate and underlying hidden flexure layer. The faceplate is patterned into a two-dimensional array of diffractive elements composed of active circular disk surrounded by an equal-area static reference surface. In the quiescent state, the active disk is coplanar with the surrounding static reference and light is reflected like a mirror. When the pixel is activated, the disk is displaced with respect to the surrounding faceplate and light scattering light into fixed diffraction angles.

The PLV™ creates images by exploiting the wave-nature of light. Light reflected active disk interferes coherently with light reflected from the surrounding static faceplate. If the active disk and surrounding faceplate are co-planar, the phase difference between reflected waves is zero (φ=0), and light is reflected like an ordinary mirror. However, if the active disks are electronically displaced by quarter-wave relative to the surrounding faceplate, the reflected waves are anti-phase (φ=π), and the specular beam is extinguished as light is scattered into fixed diffraction angles.

A key advantage of the PLV™ is its inherent analog grayscale. For intermediate phase relationships between the active disks and static faceplate (i.e. 0<φ<π), the light distribution between reflected and diffracted beams varies continuously. Thus by carefully controlling the active disk displacement, true analog grayscale is achieved. Other spatial light modulators rely on pulse-width-modulation for grayscale. However, this comes at great cost to modulation rate. The “built-in” grayscale of the PLV™ allows deep intensity resolution with zero speed penalty.

The two layer design ensures the active region does not warp with activation

An SEM image showing the PLV™ pixels

Advantages

More Pixels x More Power = More Throughput

High Speed

Due to the low mass, high tension and short stroke, PLV™ pistons can switch in less than 500ns. This is 10x faster than MEMS tilt mirrors and 1000x faster than liquid crystal spatial light modulators. Our PLV™ modules support refresh rates up to 250 kHz.

Analog Grayscale

Many spatial light modulators are binary devices: they’re either fully on or fully off. The PLV™ is different. It is an inherently analog device, allowing intensity to be continuously varied from dark to bright according to applied voltage. Amplitude resolution is limited only by the bit-depth of the electronic driver.

High Power Handling

The increased optical area of the PLV™ and its ability to accommodate flood illumination endow it with even higher power handling than the Grating Light Valve (GLV®). Current PLV™ products support CW powers of up to 1 kW and pulsed laser energies of 1mJ.

Increased Pixel Count

Due to physical die-size constraints, 1D Grating Light Valve (GLV®)s are generally limited to <104 pixels. By contrast, PLV™’s can support pixel counts >105 by exploiting the increased packing efficiency of 2D arrays.

Non-contact, High Reliability

Unlike other MEMS spatial light modulators, the PLV™ is a non-contact device and requires no lubricants inside the package. This attribute is particularly valuable in high-fluence UV applications.

Borderless Pixels

PLV™ images are formed by spatially filtering the angular content of light reflected from the grating. As a result, PLV™ images contain no dark lines between pixels. The absence of the familiar “screen door” effect results in stunning images that have been likened to “painting with light.”

Resources

Further information and application notes

PLV™ Technology

An introduction to the Planar Light Valve (PLV™), a 2D spatial light modulator that extends the capabilities of the original 1D GLV® for new applications.

Controlling the Grating Light Valve™ in Real-Time Applications

Technical discussion on the methods and systems for controlling GLV®, PLV™, and DPM™ devices in applications that require real-time adjustments and feedback.

Dynamic Gain Equalizer Presentation

A presentation outlining the principle of operation and benefits of using the GLV® device as a Dynamic Gain Equalizer (DGE) for managing DWDM channels in optical networks.

High Power MEMS Planar Light Valve

The PLV™ supports modulation of over 500W of laser power for materials processing. It provides a line beam with 1088 individually addressable pixels and 200kHz switching speed. A custom optical head complements the PLV™.

High Throughput Materials Processing

An overview of how the Planar Light Valve (PLV™) spatial light modulator enables high-throughput, multi-beam materials processing for applications like laser marking and micromachining.