Technology

MEMS-based spatial light modulators

Silicon Light Machines produces optical MEMS with highly differentiated properties relative to other spatial light modulators. Through a patented surface micromachining process, we fabricate thin-film mechanical structures capable of manipulating light with unprecedented speed and resolution. The core technology comprises electrostatically coupled micro-mirrors driven by monolithically integrated CMOS drivers. Since these low-mass mirrors deflect by only fractions of a wavelength, speeds from 10x-1000x higher than competing technologies are realized

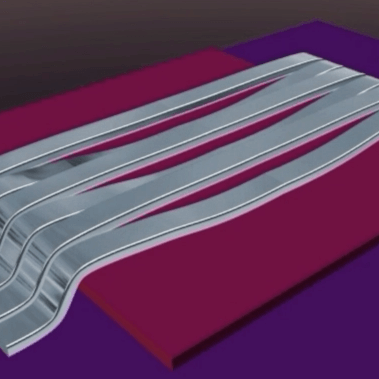

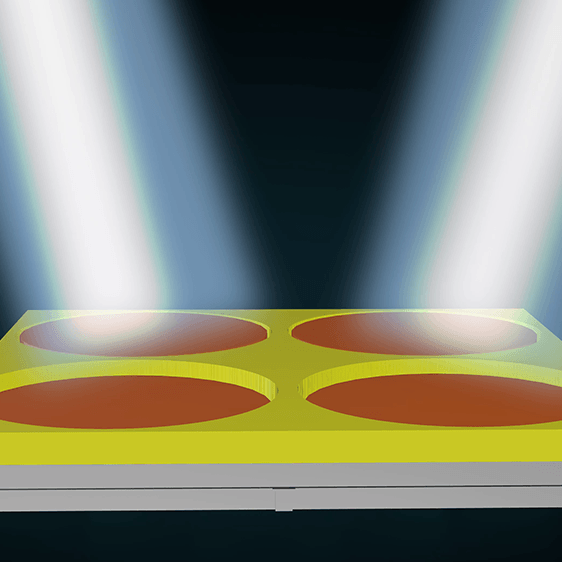

SLM’s core technology can be adapted for different applications. Micro-ribbons constitute our 1D Grating Light Valve (GLV®), whereas piston-motion membranes are used in our 2D Planar Light Valve (PLV). With straightforward modification of the MEMS, either technology can be adapted for amplitude- or phase-modulation. In contrast to tilt mirrors, our micro-mirrors move strictly perpendicular to the mirror plane, resulting in pure phase modulation. The aluminum reflective layer ensures wide spectral response: current devices support UV-VIS wavelengths and NIR versions to 1550 nm are in development.

Finally, being fabricated from 100% CMOS compatible materials, our modulators contain no organic compounds which can degrade under laser fluence. In addition, the lack of contact between moving parts eliminates mechanical wear-out. The result is unparalleled reliability and power-handling.